What is Dynamics 365 for Discrete Manufacturing Companies?

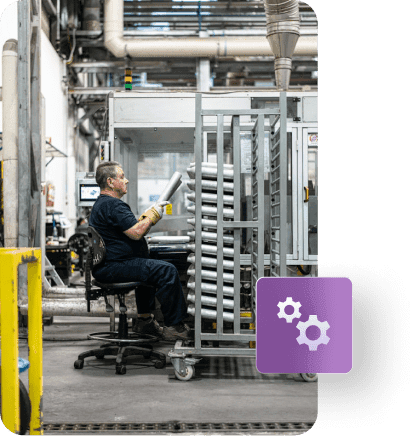

Dynamics 365 for discrete manufacturing industry helps manufacturers build products from individual parts, and each stage depends on accurate planning and clear visibility. Microsoft offers two strong ERP systems that help discrete manufacturers run daily operations with discipline and control:

1. Dynamics 365 Business Central

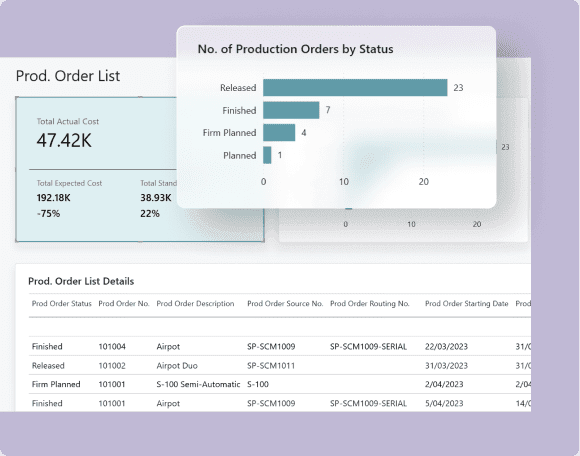

Dynamics 365 Business Central ERP for discrete manufacturing suits small to mid-sized manufacturers who want a single ERP for discrete manufacturing that covers production planning, inventory, procurement, sales, finance, and service.

Discrete manufacturers choose D365 Business Central when:

- The company has controlled operations and plans for steady growth.

- Teams need clear tracking for components, assemblies, and finished goods.

- The goal is to align sales, planning, purchasing, and production without heavy customisation.

- The business depends on accurate stock levels and stable scheduling.

- The team wants a tool that is simple to learn and easy to maintain.

2. Dynamics 365 Finance and Supply Chain Management, formerly known as Dynamics 365 Finance and Operations or D365 F&O

Dynamics 365 Finance and Operations for discrete manufacturing is chosen by large manufacturers when they handle multi-plant operations, global sourcing, detailed engineering, and advanced automation.

Manufacturers choose Dynamics 365 Finance and Operations for discrete manufacturing when:

- The business has several legal entities or serves several countries.

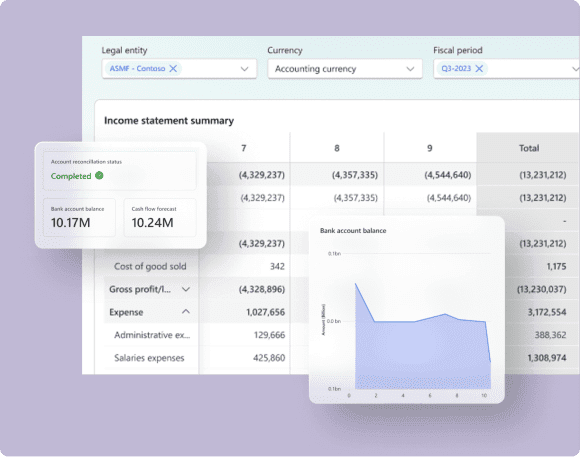

- Financial consolidation and multi-currency control are essential.

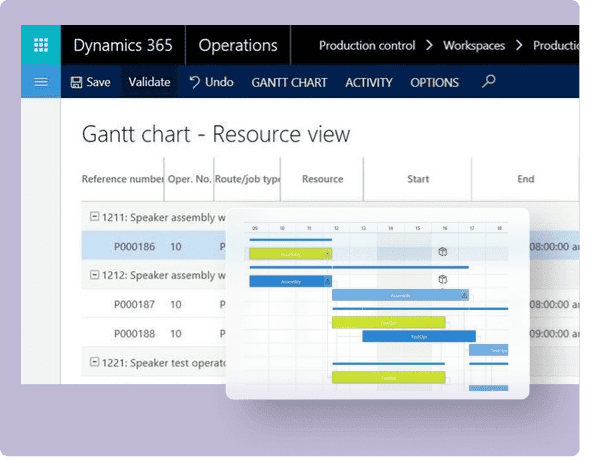

- Production cycles involve several stages with complex routing.

- The team wants deep insights into machine performance, supplier trends, and cost behaviour.

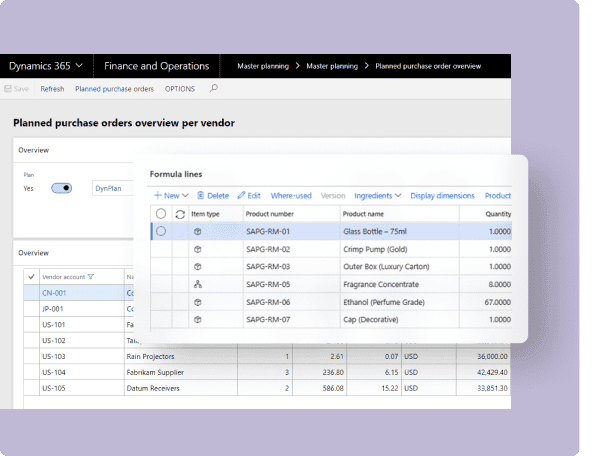

- Thousands of components require structured tracking and stable procurement cycles.

Challenges in the Discrete Manufacturing Industry

Discrete manufacturers build products that depend on parts, assemblies, and machines working in sync. Even a small gap slows the complete process. Some of the evident challenges of the discrete manufacturing industry in the UK include:

Fragmented Production Information

When production data stays in different systems, teams cannot follow work in progress correctly. This affects planning accuracy.

Paper Based Scheduling Pressure

When job cards, drawings, and routing details travel through manual steps, planning falls behind. This slows production flow.

Parts and Materials Visibility Gaps

When stock systems do not connect with planning tools, material shortages appear without warning.

Supplier Variability

When supplier records are scattered, teams cannot track delivery behaviour. This slows raw material availability.

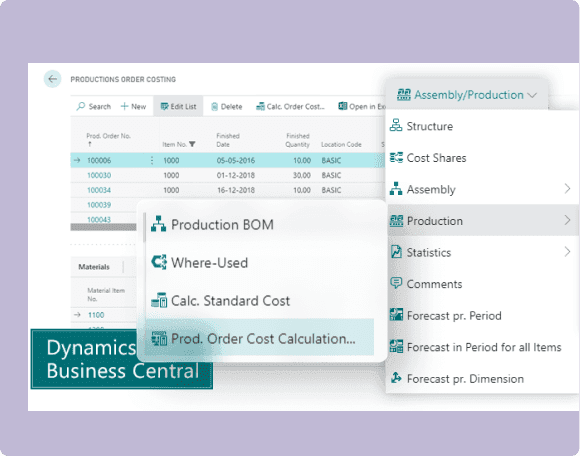

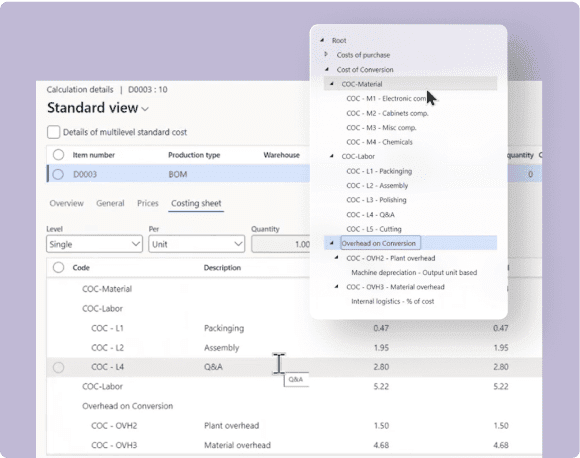

Unclear Costing and Margin View

When costing stays disconnected from procurement and production, teams cannot understand true product margins.

Engineering Updates Reaching Teams Late

When design changes do not reach production lines quickly, assembly errors appear.

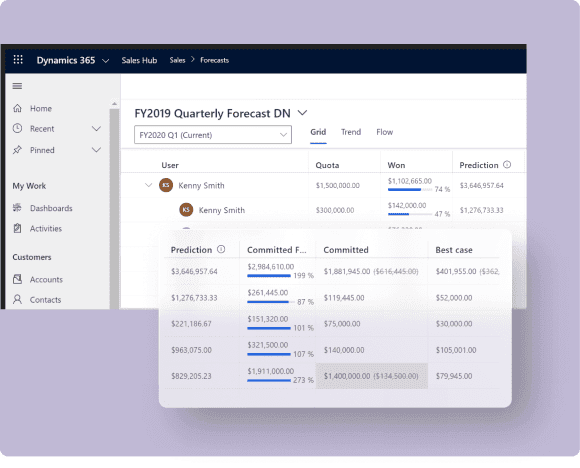

Weak Forecasting Confidence

When demand planning relies on estimates, teams cannot prepare accurate material and production schedules.

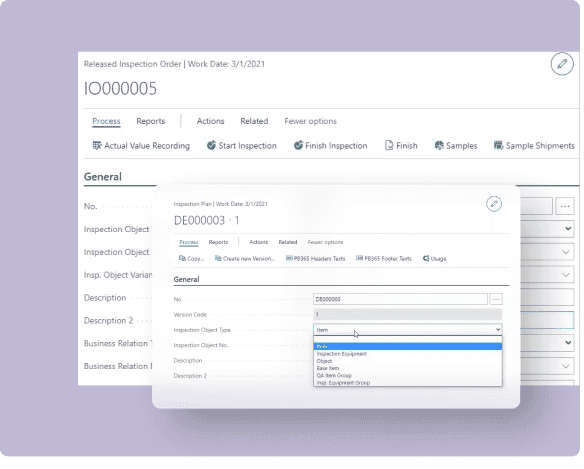

Quality and Compliance Records Spread Across Files

When quality checks depend on manual notes, teams cannot trace issues quickly.

Service Data Sitting Outside Manufacturing Records

When service history stays in isolated tools, teams cannot plan improvements based on real usage.

Why Dynamics 365 is a Strong Fit for Discrete Manufacturing

Connected Operations

Dynamics 365 keeps production, procurement, stock, engineering, finance, and service working together within one connected system.

Scalable for All Sizes

The system supports small workshops and large engineering units through flexible tools that grow with the business.

Reduced Manual Work

Automation lowers rework and manual entry, which helps teams maintain steady accuracy throughout daily manufacturing tasks.

Cloud Based Access

Cloud based tools keep teams connected, support remote work, and help maintain steady access to important information.

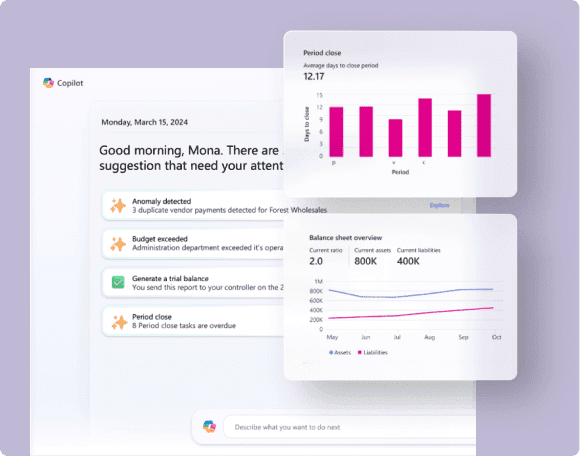

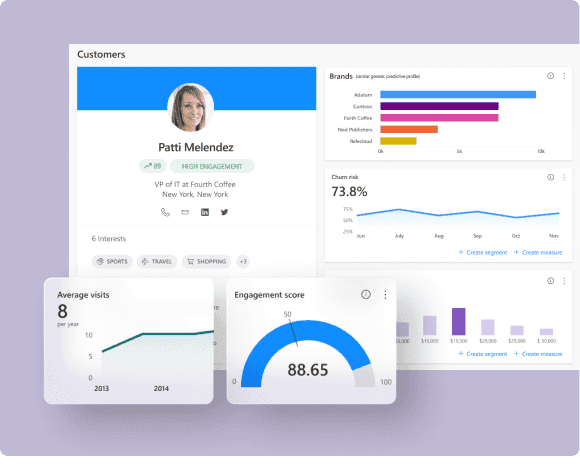

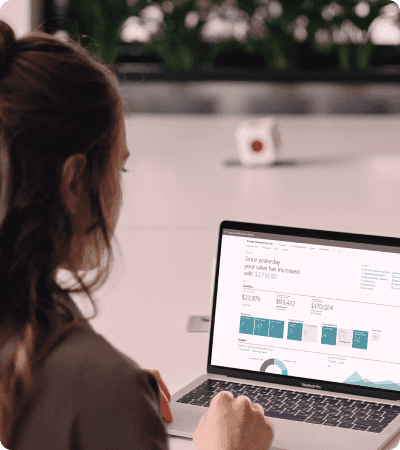

Helpful AI Insights

AI driven insights guide planning, machine utilisation, and workload balance through clear data that supports confident decisions.

UK-Ready Features

Dynamics 365 supports UK VAT rules, Making Tax Digital (MTD), landed cost calculations for imports, and practical compliance features required by UK manufacturing teams.

| Criteria | Business Central | Finance and Operations |

|---|---|---|

| Company Size | Small to mid-sized | Large enterprises |

| Users | 10–300 | 300+ |

| Operations | Single or few sites | Multi-site and global |

| Project Complexity | Basic to mid-level | Complex and detailed |

| Warehouse Needs | Moderate | Highly automated |

| Implementation Time | 2–6 months | 6–12 months |

| Cost | Lower | Higher |

| Reporting | Built-in | Deep financial consolidation |

| Flexibility | High and simple | Extensive configuration |

| Best For | Growing manufacturers | Large engineering units |

Strengthen Your Manufacturing Cycle with the Right ERP

Adopt supply chain ERP for discrete manufacturing to keep your process steady from planning to delivery.

Partnering With Dynamics Square UK

Discrete manufacturers in the UK prefer to work with a partner who understands production processes, supply chain operations, and finance.

A Dynamics 365 partner in the UK like Dynamics Square brings experience in Dynamics 365 implementation and ongoing Dynamics 365 support for discrete manufacturing companies.

Our team guides businesses across scheduling setup, production planning, stock alignment, engineering updates, supplier integration, and financial reporting.

Whether the goal is automation, cost clarity, or supply chain visibility, our specialists help bring steady improvements from the first phase.

Transform Your Manufacturing Business

Outcomes You Can Expect with Dynamics 365 for Discrete Manufacturing

- Over 95% production plan adherence and fewer last-minute schedule changes

- Faster planning to dispatch cycles

- Clear cost and margin insights

- Full supplier and component traceability

- Single dashboard for production and finance

These results reflect UK manufacturers running Dynamics 365 for discrete manufacturing with guidance from Dynamics Square UK.

Schedule A Free Consultation Today