What is the Impact of Business Central Supply Chain Management?

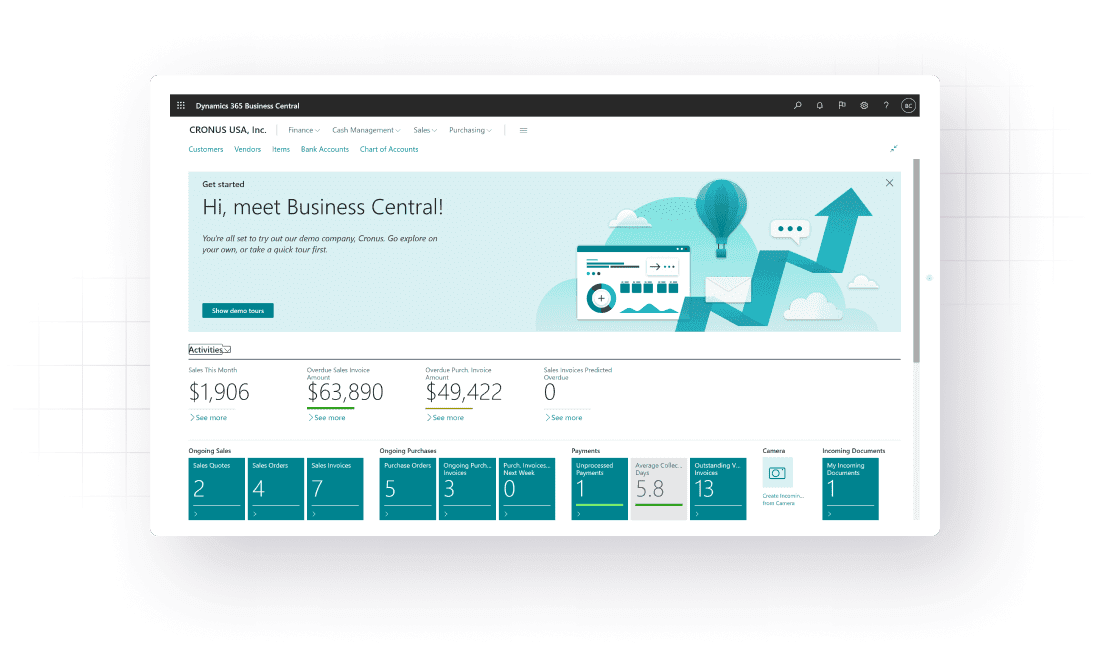

Supply chain management in Dynamics 365 Business Central eliminates the need to juggle multiple systems. It becomes your single source of truth. Each purchase order, production job, shipment, and stock movement is linked. Every department sees the same data, live.

The impact? Here are what it changes:

Purchasing aligns with real sales patterns, not assumptions

Inventory reflects what’s actually on hand, not outdated spreadsheets

Warehouses operate using data that updates automatically

Delivery teams fulfil what can be promised, not what was hoped for

Your operations begin to support your growth, not block it. Delays in supply kill demand. You need to act on time.

Unify the Flow with Business Central

Core Strengths of Dynamics 365 Business Central Supply Chain Management

D365 Business Central for supply chain creates a chain where each link strengthens the next. From planning to fulfilment, the platform ensures that no weak spots remain hidden.

Major capabilities include:

Planning and Demand Forecasting

- Real-time forecasts based on customer behaviour and seasonality

- Planning tools that adapt daily as data shifts

- Alerts for low stock, late shipments, and demand spikes

Procurement Management

- Purchase suggestions based on real consumption

- Vendor scoring based on lead time and delivery history

- Fully automated approval workflows

Inventory Control

- Live view of inventory across all sites and bins

- Stock aging analysis to reduce waste and obsolescence

- Traceability using batch and serial numbers

Warehouse Execution

- Location-based bin tracking

- Pick lists generated in real time

- Mobile access to manage inventory on the move

Production Management

- Seamless link between BOM, routing, and production jobs

- Work centre scheduling to match available capacity

- Cost tracking from raw material to finished goods

Order Fulfilment

- Sales orders tied to actual inventory and lead times

- Packing and shipping workflows inside the ERP

- Packing and shipping workflows inside the ERP

Everything functions like a supply chain should. No friction, just pure efficiency.

Your supply chain deserves clarity. Are you ready to upgrade?

Gain Full Visibility with Business CentralKey Functions in Business Central in Supply Chain Management (SCM)

Microsoft Business Central Supply Chain does not require heavy customisation to get started. It includes built-in tools that meet real business needs from day one.

These include:

Material Requirement Planning (MRP)

Master Production Scheduling (MPS)

Cycle counting and physical inventory

Automated stock transfers between warehouses

Production BOM costing and routing

Vendor performance tracking

Inbound and outbound logistics control

Shipment documentation and compliance tools

Each function reduces effort, minimises risk, and strengthens flow. Fast-track your ERP transformation for a better and more efficient supply chain with Business Central support by Dynamics Square. Get started with experts.

Schedule a Free Call Today!Business Central for Supply Chain: Ready for Any Industry

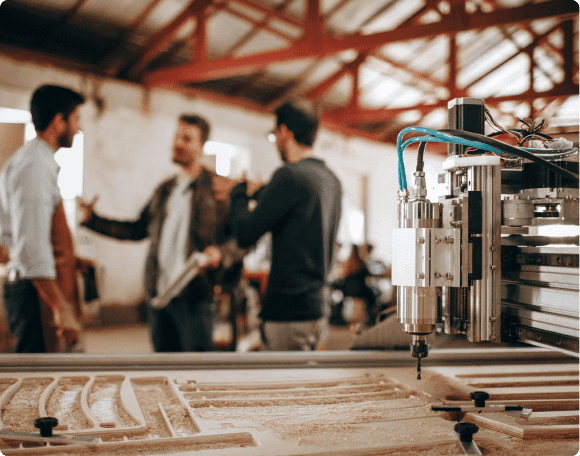

The needs of a beverage distributor differ from those of an auto parts manufacturer. But both need flow, precision, and predictability. Business Central in the supply chain in industry segments fits because it is built to flex. No two workflows are identical. The system adapts to your method, not the other way around. And Business Central is built to adapt!

Business types that use it well:

Fast-moving consumer goods

Light and heavy manufacturing

Wholesale and distribution

Equipment-based service operations

Food production and packaging

Retail operations with central warehousing

Whether you track tonnes, units, or litres, the system tracks what matters most to you. Want to see Business Central in action?

Let’s Schedule a Free Call

Fix the Weak Links and Scale with Confidence

Most businesses delay system decisions until the symptoms hurt. Delays, cost overruns, unhappy customers. By the time problems are obvious, damage is already done.

This is how businesses scale with confidence.

Copilot: A Second Brain in Business Central for Supply Chain Management

It often happens when decisions are urgent and reports are too slow. Copilot inside Business Central supports action. It analyses data and provides insights without requiring a data science team.

Key aspects:

Gives daily summaries of open issues and flagged orders

Highlights where supplier performance is dropping

Suggests purchase quantity based on real-time usage

Automates document generation and communications

Copilot is not an assistant. It becomes your second brain, monitoring every corner of your operation.

Learn More